Home / All / Pipe Butt Fusion Machines / Automatic Butt Fusion Welder /

SWT-V1000 CNC 630-1000mm Welding Range Manual Butt Fusion Welding Machine For PVC, PE, PP, PVDF | MM-Tech

Categories

- Sheet Butt Fusion Machines

- Sheet Bending Welding Machines

- Combined Bending But Fusion Machines

- Plastic Cutting Machines

- CNC Engraving Machines

- Chemical Tank Spiral Winding Machine

- Extrusion Welder

- Pipe Butt Fusion Machines

- Pipe Socket Fusion Machines

- Electrofusion Machines

- HDPE Pipe Fitting Machines

- Hot Wedge Welder

- Hot Air Welder

- Pipe Welding Tool

- Tarpaulin Welder

- Welding Test Tools

- Geomembrane Welders

- Roof Welders

SWT-V1000 CNC 630-1000mm Welding Range Manual Butt Fusion Welding Machine For PVC, PE, PP, PVDF | MM-Tech

| Categories | Automatic Butt Fusion Welder |

|---|---|

| Brand | MM-Tech Thermoplastic Welding Equipment Manufactur |

| Model | SWT-V1000 CNC |

| Certificate | CE, ISO9001 |

| Packing Material | 1 Set |

| MOQ | Plywood Box |

| FOB port | GuangZhou |

| Terms of Payment | L/C, T/T |

| Update Time | Apr 27,2025 |

Detail Information

Detail Information

|

Hydraulic Butt Fusion Machine SWT-V1000A CNC 630MM-1000MM (24''IPS - 42''IPS) Product Details |

|||

|

WELDING RANGE O.D.

|

630MM - 1000MM

|

PISTON AREA

|

23.06cm²

|

|

POWER SUPPLY

|

380V±110%, 50/60HZ

|

TEMPERATURE RANGE

|

MAX. 320ºC

|

|

HEATER POWER

|

17.5KW

|

PACKING DIMENSION

|

2550*1850*1800 MM

|

TRIMMER POWER | 3.0KW | 1600*1150*1900 MM | |

PUMP POWER | 2.2KW | 800*350*400 MM | |

WORKING PRESSURE RANGE | 0 - 140 BAR | GROSS WEIGHT | 2502KGS |

V-CNC series Characteristics | |||

WELDING CONTROL SYSTEM | FULLY MONITORED BY CNC CONTROL UNIT | ||

DATA LOGGING CAPACITY | 2000 REPORTS | ||

WELDING MONITORING SYSTEM | AMBIENT TEMPERATURE, INPUT VOLTAGE, HEATING TEMPERATURE, WELDING PRESSURE, WELDING TIMES, HEATING OPERATION, TRIMMING OPERATION, MEMORY CONTROL. | ||

WELDING STANDARD | DVS, ISO, WIS, UNI AND OTHERS UPON REQUEST | ||

LANGUAGES | AVAILABLE UPON REQUEST | ||

WARRANTY PERIOD | 2 YEARS | ||

Product Specification

Product Features

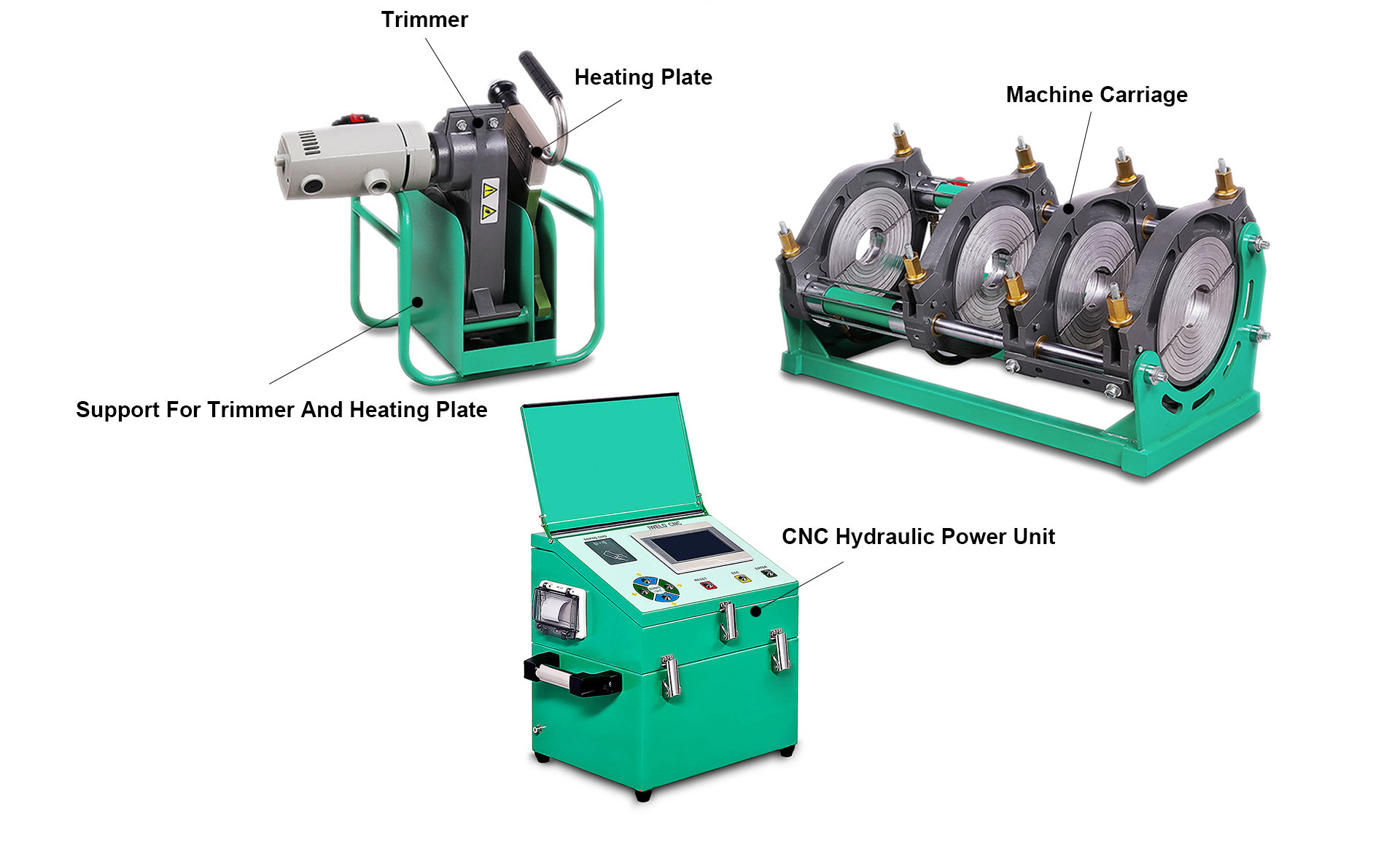

Basic Frame

- Oil seal kit, origins from Germany, make sure that the

pressure performance stays in a more stable way.

- 4sets quick coupling helps the operator to prepare the

machine better before and after welding, and we use

STUCCHI which from Italy ensures no hydraulic oil leakages

when unplug or plug in.

- Using an integral shaft (top chromate treatment) instead

of the assembled shaft, ensure the chassis strength to

avoid possible frame twist or deform when dragging the

pipe with extreme parameters.

Heating Plate

- We use Dupont from the USA for coating the heating plate, which is

the best in the industry. It's many stickers on an aluminum plate, more

non-sticky to plastic pipes surface. The temperature deviation of

different points on the heating plate is 2-3 degrees (small size machine)

and 5-6 degrees (big size machine).

Heating Plate

- We use Dupont from the USA for coating the heating

plate, which is the best in the industry. It's many stickers

on an aluminum plate, more non-sticky to plastic pipes

surface. The temperature deviation of different points on

the heating plate is 2-3 degrees (small size machine) and

5-6 degrees (big size machine).

Trimmer

- Safety Switch, which guarantees the operators' security, even with power

on, the trimmer will not be running if operators do not press the button.

Support

- Ergonomic design

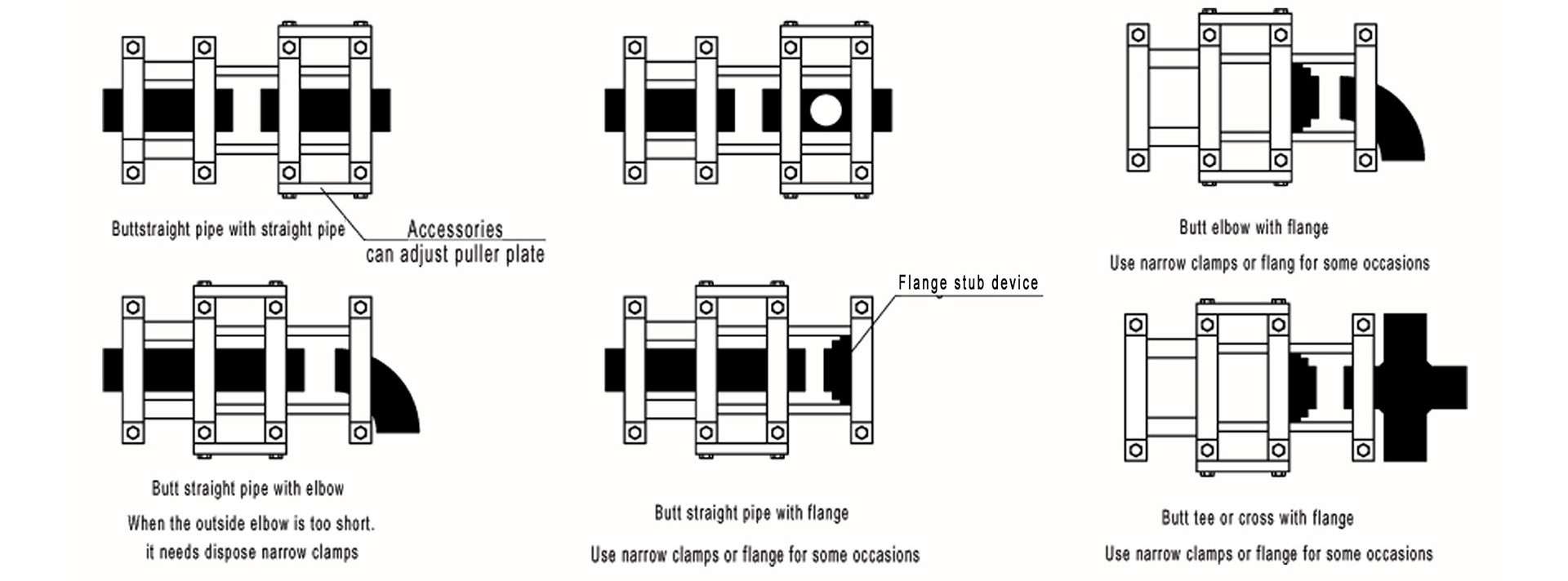

Welded Thermoplastic Tube Type

Welding Type

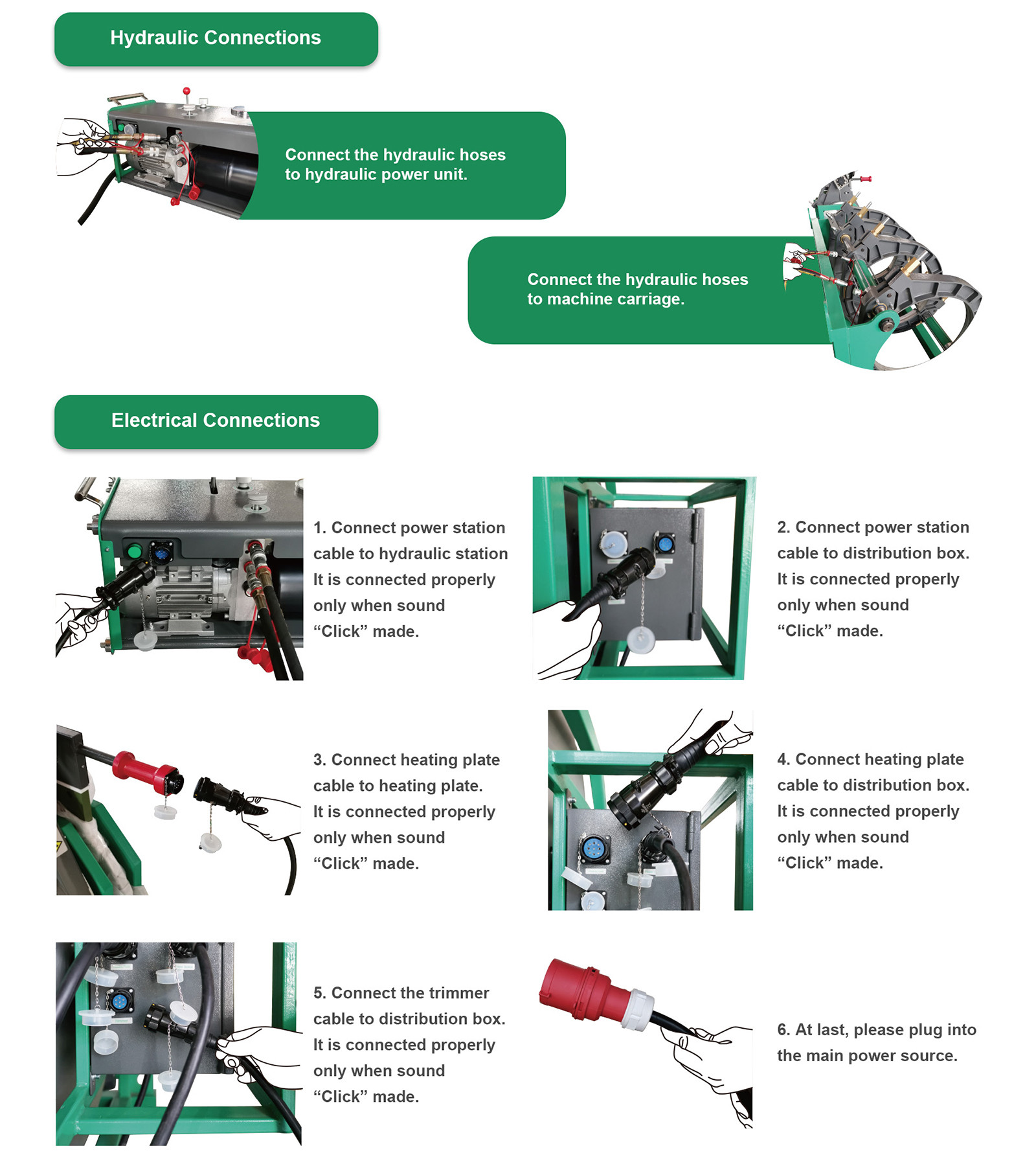

Steps For Usage

Welding Type

Review

- Loading...

Related Products

Request a Quote

Fill all information details to consultwith us to get sevices from us

- Tel

- *Title

- *Content

Navigation

Categories

- Sheet Butt Fusion Machines

- Sheet Bending Welding Machines

- Combined Bending But Fusion Machines

- Plastic Cutting Machines

- CNC Engraving Machines

- Chemical Tank Spiral Winding Machine

- Extrusion Welder

- Pipe Butt Fusion Machines

- Pipe Socket Fusion Machines

- Electrofusion Machines

- HDPE Pipe Fitting Machines

- Hot Wedge Welder

- Hot Air Welder

- Pipe Welding Tool

- Tarpaulin Welder

- Welding Test Tools

- Geomembrane Welders

- Roof Welders

WhatsApp

Wechat